Why Agha Steel is Better?

آغا اسٹیل:

The Art Of Asal Steel-Making

Agha Steel is the only company in Pakistan possessing a 100% EBT Electric Arc Furnace Technology which is globally considered as a steel making technology. Built with inherent high efficiency allowing us to solely produce a variety of grades of steel that are not only superior but unmatched in quality, strength, resilience and bonding capabilities.

Compared to other companies in Pakistan which posses the outdated and globally banned induction furnace(steel melting technology), the Electric Arc Furnace uses multiple types of scrap (shredded, DRI, LMS, HMS, HBI, pig iron etc.) to produce 100% refined Steel. The main advantage of DRI usage is to dilute the Cu & Sn; which is not possible with induction furnace.

EAF technology also has the provision to eliminate unwanted content (through Decarbonization & Dephosphorization) in steel that makes it weaker with the passage of time; producing 100% Refined Steel Rebars that stands the test of time and nature.

In addition to this, Tramp & Trace elements are better controlled in an Electric Arc Furnace, also the batch/heat capacity of Agha Steel is highest among its competitors that is 45-50 MT/batch.

Aided With An Exclusive Ladle Refining Furnace Technology

At Agha Steel Electric Arc Furnace is coupled with Ladle Refining Furnace (LRF), which initiates a secondary metallurgy process to remove the sulphur from molten steel.LRF also helps to remove non-metallic inclusion such as oxides, sulfides, nitrides etc..and precisely controls the chemistry of the molten metal through an allowing system, enabling the steel to reach the perfect oxygen ppm according to required grades and eliminates silicon aswell; ensuring every Steel Bar produced by Agha Steel is 100% ASAL, every time.

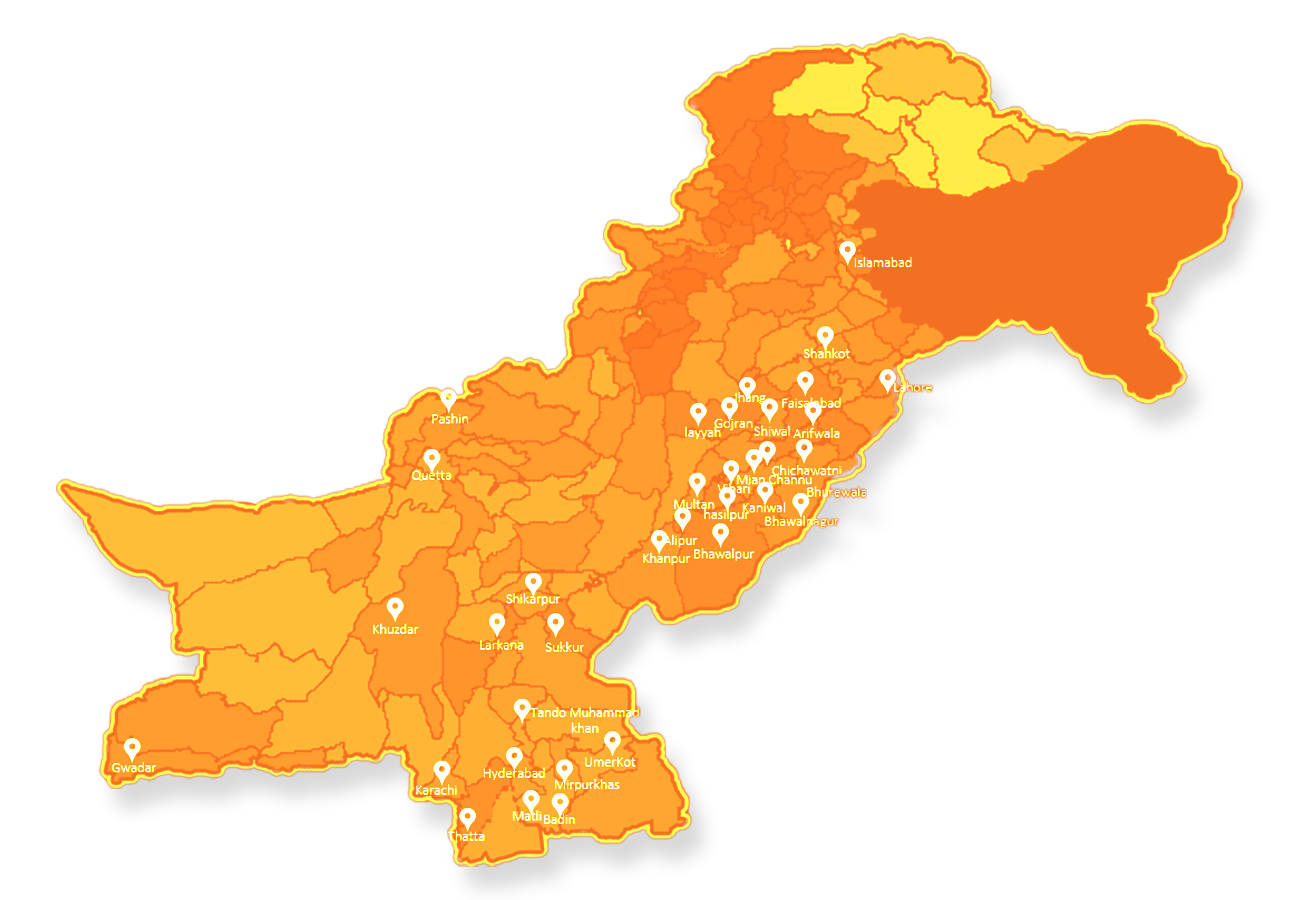

کمرشل پارٹنرز

NUMBERS SPEAKS

We are commited to provide safe

solutions to many industries

Projects are Completed

Professional Contractors

Industries Served

Happy Customers